Total Game Restoration

The primary focus of our business is to offer our customers a COMPLETE game restoration service. Customers are able to ship their machine to us and we will transform the game into an example that would surpass the factory ‘as-new’ condition.

Game Setup & Documentation

Games arrive and are initially setup for evaluation. Missing parts, broken or damaged parts are noted and replaced when we order materials for your project. After the game is setup in our workshop, the teardown can begin

Game Teardown

At this point, your machine is systematically broken down into various sub assemblies and components. Trim options, hardware and circuit boards are sent out to various contractors who we work with on a local level. Every component of the machine will be restored or refinished in some way during the restoration process

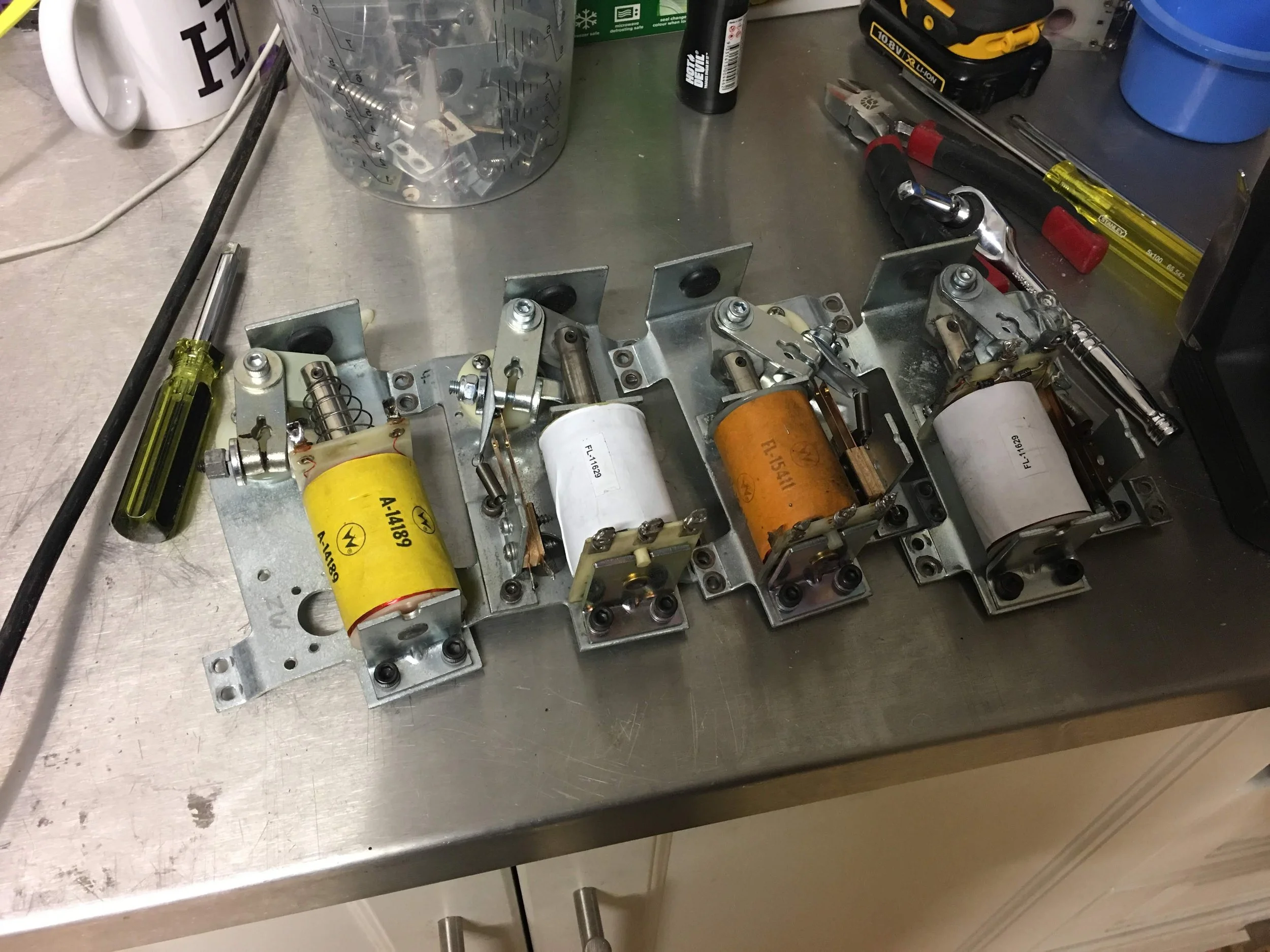

Restoration of existing components

This stage is the most critical, as it will ultimately form the foundations for how the restored machine will look once fully assembled. While the various components are out with other contractors, we are busy restoring all associated hardware that make the game work.

All metal is tumble polished or nickel plated. All painted surfaces are repainted. All plastic is polished. What we are saying is - we do our very best to replicate the original factory process while bringing it up to a modern day standard

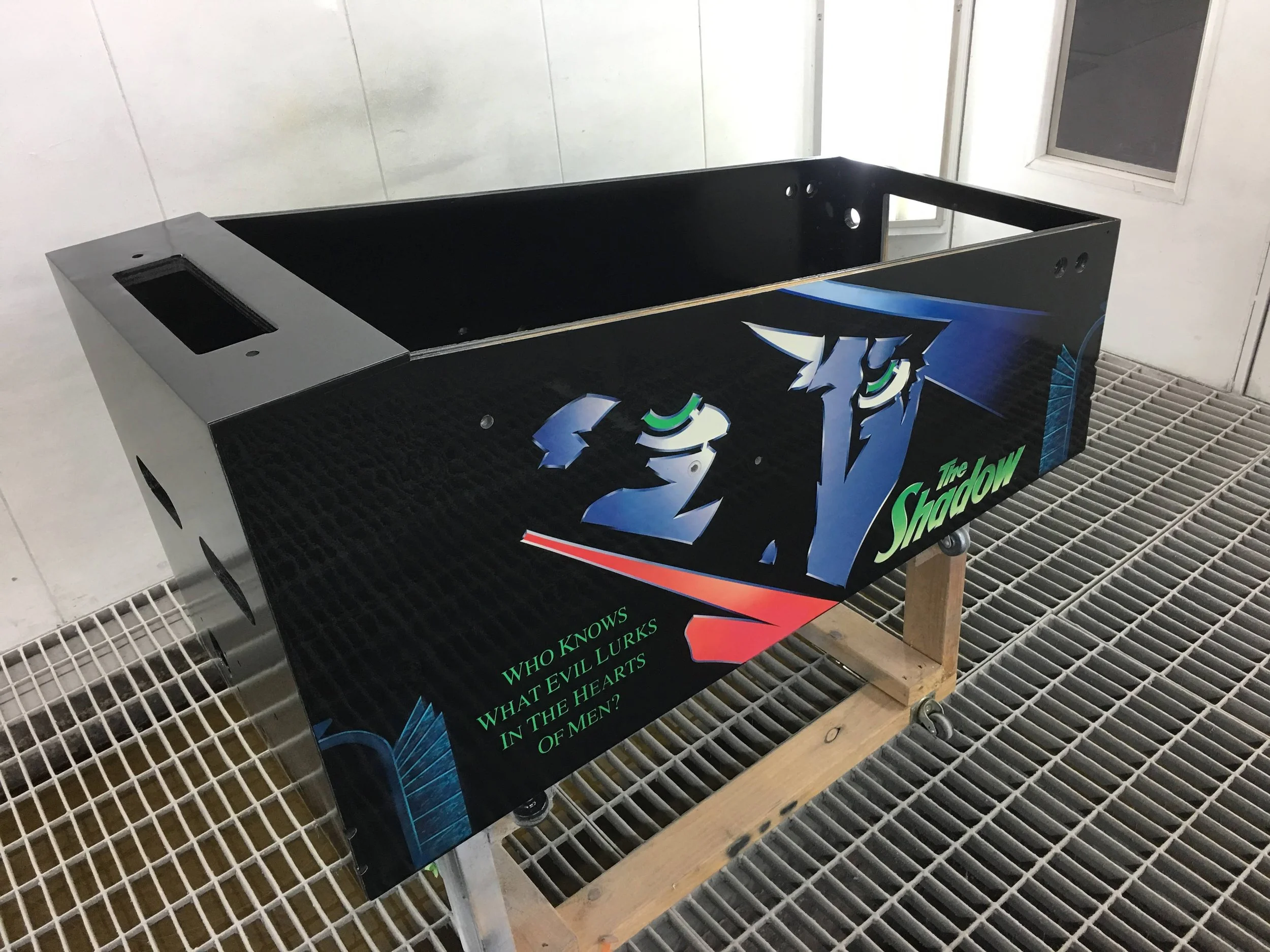

Creation of new components

While we pride ourselves on our restoration process, supply of suitable quality base games are getting harder and harder to find. To combat this - we are now able to supply owners with a brand new cabinet to compliment their restoration project. While the original may be restorable, it may be more economical to begin with a new cabinet and eliminate the tedious hours required to faithfully restore a beat up old cabinet. We can finish these cabinets in many styles, factory look over spray on the floor or something truly high end.

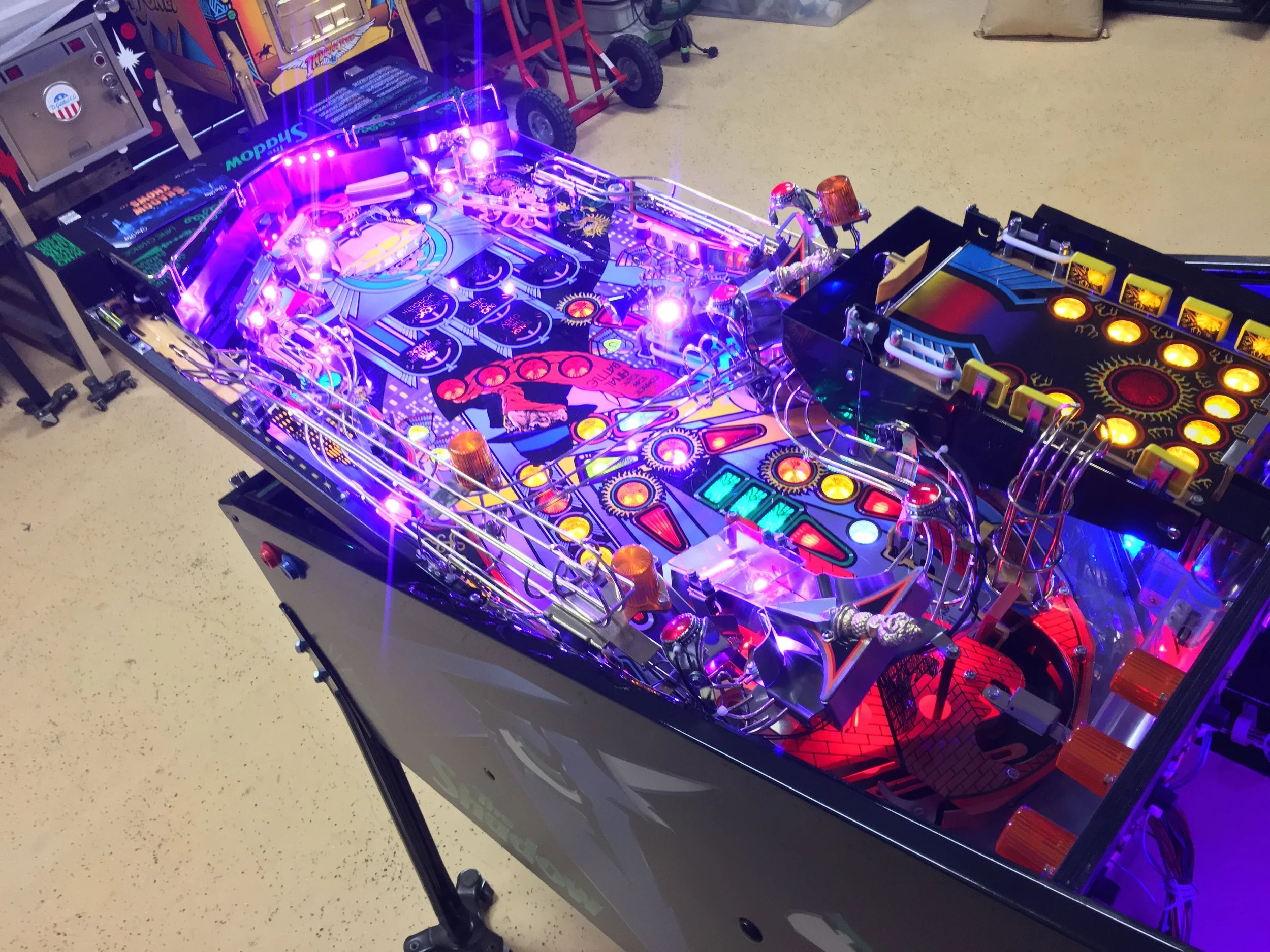

Reassembly Stage

This is where all of the above stages come together and the final product starts to take shape. Contracted components are back at the assembly shop, our restored original pieces and new components are ready to go. At the end of the reassembly stage its on to final testing and factory burn-in.

Final Stage and completion of project

Game is thoroughly tested and played to inspect the overall fit and finish of the game. The game is also put through a burn in process which helps find any bugs and gremlins the game may display.

The machine is detailed and then photographed in its final form. Local clients are invited to come and inspect the completed project, and detailed photos are provided for interstate clients.

Shipping and packing

Games are shipped all over the country. These are not 'container pins' and such they require the highest quality crating to ensure they leave our facilities and arrive to their owners in the exact same condition. We supply crates for these high end examples. They are built as required and are a small price to pay for peace of mind during transport. Shipping companies while excellent - will NEVER care as much about your pinball machine as much as we do, or YOU do.